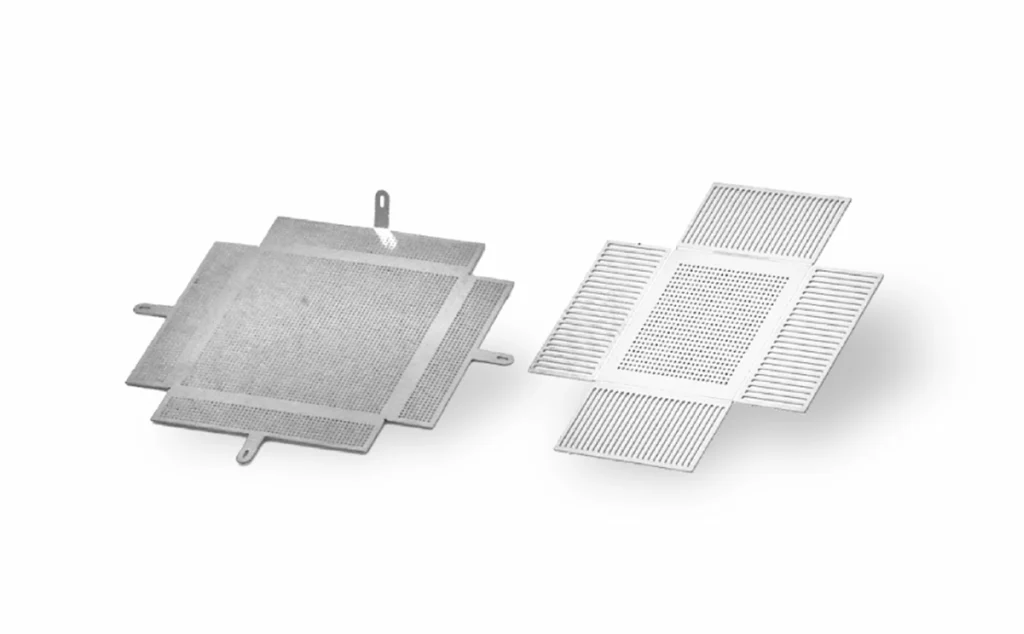

Precision forming is a crucial part of modern metal manufacturing, enabling the production of complex and high-performance components. In this age of innovation and efficiency, precision forming has revolutionized the way metal components are crafted, delivering precise, intricate parts that can meet the most stringent specifications. The specialized metal forming process involves accurately shaping metal materials, ensuring minimal material waste and impeccable dimensional consistency. It allows manufacturers to craft components with intricate geometries, exceptional mechanical properties, and tight tolerances by harnessing advanced techniques like press brake forming, roll forming, and hydroforming. At E-Fab, we’re experts at forming the exact part from metal materials that work with existing components or detailed design specifications. Our manufacturing experts perform a wide range of precision forming techniques and processes, delivering precision metal products. Every piece we produce is carefully finished and put through an exacting Quality Assurance process before delivery.

Precision forming has fast become a cornerstone of modern manufacturing, allowing manufacturers to create intricate and complex parts by shaping metal materials with exceptional accuracy and meticulous detail. Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and intricate geometries, resulting in components with superior structural integrity and consistent dimensional characteristics. Precision metal forming not only enhances the overall structural integrity of products but also contributes to the reduction of post-processing requirements. Enabling the production of high-performance components that meet stringent specifications and drive technological innovation, precision forming is used for a myriad of industries, ranging from aerospace and automotive to electronics and healthcare.

Precision forming has fast become the preferred forming method in metal manufacturing, but what sets it apart? Unlike general forming, which focuses on basic shaping with acceptable tolerances, precision metal forming employs advanced techniques and value added processes, such as computer-controlled machinery and finely-tuned tooling, to achieve extremely tight tolerances and intricate geometries. The level of detail it can deliver ensures consistent dimensional attributes across multiple components, reducing variations and enhancing overall product quality.